The latest chenille yarn machine innovations for 2026 are revolutionizing textile manufacturing. These advancements significantly boost production efficiency, elevate yarn quality, and champion sustainability. Such cutting-edge technologies introduce transformative capabilities. They are poised to redefine the industry’s operational landscape. Manufacturers gain unprecedented advantages in output and product excellence.

Key Takeaways

- New chenille yarn machines use AI and IoT. This makes production faster and better. It also needs less human work.

- These machines make chenille yarn much better. They use new ways to feed fibers and twist yarn. This makes yarn strong and soft.

- The new machines help the environment. They save energy and make less waste. They also run quieter.

- These changes help companies make more yarn for less money. They can also make new kinds of yarn. This helps them do better in business.

Automation and Smart Control in Chenille Yarn Machine Innovations

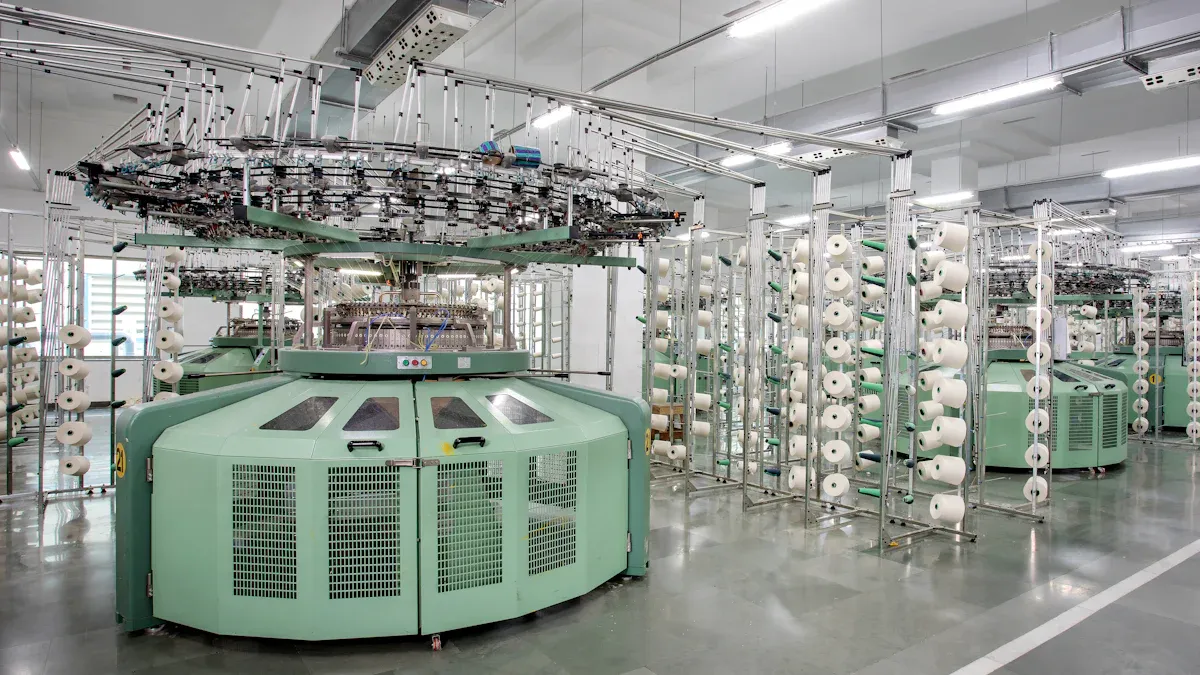

Modern textile manufacturing relies heavily on advanced automation. New chenille yarn machine innovations integrate smart control systems. These systems significantly improve efficiency and product quality. They also reduce the need for manual intervention.

AI-Powered Process Optimization

Artificial intelligence (AI) drives significant advancements in chenille yarn production. AI-powered systems optimize various processes. They predict yarn properties with high accuracy. Artificial Neural Networks (ANNs) are crucial for this prediction. They also contribute to general process optimization in textiles. Specifically, Radial Basis Function Neural Network (RBFNN) models predict yarn properties like abrasion resistance. These models also aid in process optimization.

AI systems predict maintenance needs. This reduces machine downtime. They analyze real-time data. This ensures consistent yarn quality. Machine learning algorithms automatically fine-tune machine settings. This maximizes efficiency and minimizes waste. AI systems reduce material waste. They implement precise relaxation techniques during fabric preparation. Machine learning algorithms optimize raw material selection. They also adjust processing parameters. This directly leads to less waste. Smart sensors monitor material flow. They ensure precise yarn feeding. This minimizes material waste.

IoT Integration for Remote Monitoring

The Internet of Things (IoT) connects chenille yarn machines. This allows for real-time monitoring and control. The LAGEFILL SW200 L1 L2 fancy yarn twister includes an integrated control platform. This platform provides a centralized interface. Users can easily adjust parameters and monitor production in real-time.

Many modern machines incorporate smart manufacturing concepts. For example, Tong Yang Moolsan’s machines use sensors and intelligent control systems. These systems collect and analyze real-time data. This enables process optimization and quality improvement. These machines integrate with digital platforms. This facilitates remote monitoring, operation, and management. This benefits large textile enterprises with multiple production facilities. Karl Mayer’s machines feature advanced digital control systems. These systems allow real-time monitoring and adjustment of production. They also support remote operation and maintenance for large-scale plants. Modern chenille machines use PLC intelligent control systems. These systems enable real-time monitoring and automated process adjustments. They seamlessly integrate with servo drives.

Robotics in Material Handling

Robotics streamline material handling in chenille yarn factories. Robotic systems perform automated doffing. They also manage material transport. These systems automatically doff full packages. They transport them between different processing stages. They also load empty carriers. This automation significantly reduces manual handling. It helps prevent damage to delicate yarn structures. It also improves overall equipment efficiency. This happens by minimizing downtime.

Enhancing Chenille Yarn Quality and Versatility

New chenille yarn machine innovations significantly improve yarn quality and expand design possibilities. These advancements focus on precise control at every production stage. They ensure consistent, high-quality output.

Precision Fiber Feeding Mechanisms

Modern machines feature highly precise fiber feeding mechanisms. These systems ensure consistent yarn production. A compound needle, with its independently moving stem and tongue, forms loops accurately. This ensures uniform fabric quality. It is ideal for fine-gauge fabrics. Advanced electronic tension control systems monitor and adjust yarn tension dynamically. Constant yarn feed devices maintain uniformity. Servo-controlled feeders ensure accurate speed adjustments. Sensors adjust feed rates in real-time based on yarn thickness. Multi-channel feeding systems offer independent tension adjustments for multi-component yarns. Optimized software controls improve synchronization. Sand tables assist in controlling yarn delivery. Yarn supports stabilize large yarn rings. This prevents tangling during high-speed knitting. High-precision gear systems minimize mechanical loss and reduce noise. They also increase operational longevity. Electrical control systems monitor yarn tension and needle speed. Programmable logic controllers (PLCs) automate operations. Integrated sensors ensure consistent stitch density.

Advanced Twisting and Cutting Technologies

Advanced twisting and cutting technologies are crucial for superior chenille yarn. High-precision cutting systems improve the uniformity of chenille yarn pile height. These systems ensure each yarn strand has a consistent, plush texture. This precision prevents unevenness. It results in a more luxurious and durable final product. New twisting methods also enhance yarn strength and reduce shedding.

Multi-Material Processing Capabilities

Modern chenille yarn machines now process a wider range of materials. Manufacturers can combine chenille with polyester yarn. They can also blend chenille with flat embroidery, sequins, or cording. This capability opens new avenues for product development. Processing delicate materials like metallic yarns or smart yarn components presents challenges. These include tarnishing, breakage, and maintaining consistent quality. New machines overcome these issues. They handle fragile components with care. This ensures precise integration of functional elements. They also prevent defects like the ‘Strip-Back Effect’ in core-spun yarns. This versatility allows for innovative textile designs.

Sustainable and Energy-Efficient Chenille Yarn Machine Innovations

The textile industry increasingly prioritizes sustainability. New chenille yarn machine innovations reflect this focus. They integrate advanced technologies to reduce environmental impact and optimize resource use.

Energy-Saving Motor and Drive Systems

Modern chenille yarn machines feature highly efficient motor and drive systems. Each rotary head now operates with an independent high-speed motor. This design ensures steady rotation, low noise, and minimal speed differences. These motors can reach speeds of 24000 rpm. Stepper motors drive the rollers, providing smoother rotation, reduced noise, and lower breakage rates. A stepper motor with a precise planetary reducer controls lifting movement. This ensures stable winding, reliable operation, and easier unwinding. Independent motor control allows for convenient craft adjustments via touchscreen. It also enables automatic shutdown and easier doffing when bobbins are full. These advancements significantly cut energy consumption.

Waste Reduction and Recycling Integration

Manufacturers integrate waste reduction strategies into modern chenille yarn production lines. Industry 4.0 principles are key to this effort. These include IoT-enabled machinery and data analytics. Sensor-driven automation optimizes resource utilization. Predictive maintenance reduces machine downtime. These technologies align with sustainability goals by minimizing waste and energy consumption. Advanced robotics also enable precise, automated production of chenille yarns. Robotics contribute to consistent quality and reduced waste. These innovations support sustainable manufacturing by reducing energy consumption and minimizing environmental impact.

Reduced Noise and Vibration

New machine designs significantly reduce noise levels in chenille yarn manufacturing facilities. Independent high-speed motors power each rotary head. This ensures stable rotation and inherently low noise levels. Stepper motor-driven rollers also contribute to quieter operations. They facilitate smoother movement and consequently reduce noise output. These design choices create a more comfortable and safer working environment for operators.

Impact of Chenille Yarn Machine Innovations on the Textile Industry

Increased Production Efficiency and Cost Savings

New chenille yarn machine innovations significantly boost production efficiency. They also lead to substantial cost savings for textile manufacturers. Machines like the Savio Orion Autoconer reduce labor costs. They also decrease production downtime and minimize waste. Their precision engineering reduces yarn breakages. This directly leads to cost savings and increased profitability. The widespread use of these textile machines streamlines production. It increases overall efficiency. Advanced automatic chenille machines contribute to cost savings. They significantly reduce downtime. This happens through integrated predictive maintenance and automated fault detection. These machines also feature easy-to-use interfaces. This ensures smooth operation, reliability, and cost-effectiveness. This makes them ideal for large-scale textile production. The Autoconer X5 automates various processes. It reduces manual labor. It increases overall efficiency through precision engineering, intelligent software, and advanced robotics. This ensures faster turnaround times, improved quality control, and reduced costs. It also includes energy-saving measures. An intelligent waste management system minimizes yarn wastage. This conserves resources and reduces production costs.

New Product Development Opportunities

The versatility of new chenille yarn machine innovations opens many new product development opportunities. These advanced computerized spinning machines enable the creation of innovative fancy yarns. Examples include chenille, bouclé, and loops. These versatile yarns add unique characteristics to fabrics. They enhance their value. They also allow for the development of distinctive, high-quality designs. Manufacturers can create premium and bespoke products. This technology empowers them to craft exclusive items. These items demonstrate superior craftsmanship and design. While apparel applications currently dominate the use of decorative fancy yarns, the home decor sector shows accelerated adoption. This includes items like upholstery and accent pieces. This indicates a growing opportunity for these yarns, including chenille, in non-apparel segments.

Competitive Advantage for Manufacturers

These advancements provide a significant competitive advantage for manufacturers. Companies adopting these technologies can produce higher quality yarn more efficiently. They can also offer a wider range of innovative products. This allows them to meet evolving market demands. It also helps them stand out from competitors. The ability to reduce operational costs and minimize waste further strengthens their market position. Manufacturers can invest in research and development. They can explore new applications for chenille yarn. This continuous innovation ensures long-term success and market leadership.

The 2026 update in chenille yarn machine technology marks a significant leap forward. These innovations offer unprecedented levels of automation, quality, and sustainability. They represent foundational shifts. These shifts will redefine the chenille yarn industry for years to come. Driving efficiency, expanding creative possibilities, and promoting environmentally responsible manufacturing are key outcomes.

FAQ

How do AI and IoT improve chenille yarn production?

AI optimizes processes, predicts maintenance needs, and ensures consistent yarn quality. IoT connects machines for real-time monitoring and control. This integration significantly boosts efficiency and reduces manual intervention.

What new features enhance chenille yarn quality?

Precision fiber feeding mechanisms ensure consistent yarn production. Advanced twisting and cutting technologies improve pile uniformity and yarn strength. Multi-material processing capabilities allow for diverse and innovative yarn blends.

How do these innovations contribute to sustainability?

Energy-saving motor and drive systems reduce power consumption. Waste reduction strategies, like optimized material use, minimize environmental impact. Reduced noise and vibration also create better working conditions for operators.

What competitive advantages do manufacturers gain from these innovations?

Manufacturers achieve higher production efficiency and significant cost savings. They can develop new, versatile products. This allows them to meet evolving market demands and maintain a strong competitive edge.

Post time: Jan-28-2026

Phone: +8613567545633

Phone: +8613567545633 E-mail: lanxiangmachine@foxmail.com

E-mail: lanxiangmachine@foxmail.com