The best Chenille Yarn Machines manufacturers in China earn recognition for their innovation, product quality, after-sales support, and strong market reputation. This post delves into specific companies consistently meeting these high standards. It provides a direct answer to your question. We highlight key players such as LANXIANG MACHINERY, KINGKANGDA, and JIANGSU NEW VICTOR INDUSTRIAL CO., LTD. These companies are known for their advanced technology and reliable machinery.

Key Takeaways

- Top Chinese manufacturers of Chenille Yarn Machines are known for new ideas, good product quality, and helpful support after you buy the machine.

- When choosing a machine, look at how new its technology is, how well it performs, how strong and long-lasting it is, and what other customers say about the company.

- Companies like LANXIANG MACHINERY, KINGKANGDA, and JIANGSU NEW VICTOR INDUSTRIAL CO., LTD. are leaders in making these machines in China.

- Automated machines work faster, save money on labor, make yarn that is always the same good quality, and help prevent problems before they happen.

Key Criteria for Evaluating Chenille Yarn Machines Manufacturers

Technological Innovation and Machine Performance

Leading Chenille Yarn Machines manufacturers consistently invest in research and development. This commitment introduces new technologies and improves product performance. Advanced automation and precision are hallmarks of top brands. Many machines feature user-friendly interfaces, which reduce training time and operational costs. Manufacturers also design machines for adaptability to various local raw materials, including cotton, silk, and synthetic fibers. This allows producers to utilize local resources effectively. Modern machines often include high-speed capabilities with energy-saving features. They also incorporate modular designs for easy upgrades and part replacement. Advanced spinning technology produces yarn with fewer defects and greater uniformity. Real-time monitoring systems help operators detect problems early and maintain consistent quality. Features like automatic doffing and sophisticated yarn tension control further enhance machine performance.

Product Quality and Durability

The quality and durability of chenille yarn machines directly impact production efficiency and longevity. Manufacturers known for robust construction build machines that withstand continuous operation. The integration of smart sensors allows for predictive maintenance and optimal performance. High-quality components ensure consistent output and reduce the frequency of breakdowns. Durable machines provide a better return on investment over their operational lifespan. They also minimize downtime, which is crucial for maintaining production schedules.

After-Sales Service and Support

Excellent after-sales service is a critical factor when selecting a manufacturer. Reliable support ensures smooth operation and quick resolution of any issues. This includes technical assistance, spare parts availability, and maintenance services. For instance, JIANGSU NEW VICTOR INDUSTRIAL CO., LTD., a prominent manufacturer, typically provides an engineer response within 24 hours. This rapid response minimizes production interruptions. Comprehensive support packages often include installation assistance and operator training. Strong after-sales service builds long-term trust and partnership between the manufacturer and the client.

Market Reputation and Customer Reviews

Market reputation offers a clear indicator of a manufacturer’s reliability and product quality. Positive customer reviews consistently highlight a company’s commitment to excellence. A strong market standing reflects consistent machine performance and high customer satisfaction. Prospective buyers often consult industry forums, trade publications, and specialized exhibitions. These resources provide valuable insights into a manufacturer’s operational history and client experiences.

Customer testimonials frequently detail specific advantages. They might praise machine efficiency, durability, or the responsiveness of technical support. A manufacturer with a long history of positive feedback demonstrates its ability to meet and exceed client expectations. This track record builds trust within the industry. It also assures new customers about their potential investment. Companies earn their reputation through years of delivering reliable products and exceptional service. This includes timely delivery, accurate product descriptions, and effective problem resolution.

Furthermore, a robust reputation often signifies a manufacturer’s financial stability and long-term commitment to the market. Companies with excellent standing are more likely to invest in continuous innovation and maintain high production standards. They also tend to offer better warranty terms and readily available spare parts. This commitment ensures long-term operational support for their machinery. A strong reputation also suggests a manufacturer adheres to international quality standards and ethical business practices. This provides an additional layer of assurance for global buyers.

Evaluating market reputation and customer reviews helps buyers make informed decisions. It minimizes the risks associated with purchasing high-value industrial equipment. Ultimately, a well-regarded manufacturer provides greater peace of mind and a more secure investment. This is especially true when selecting Chenille Yarn Machines manufacturers. Their reputation directly impacts the long-term success of a textile operation.

Top Chenille Yarn Machines Manufacturers in China

This section highlights leading Chenille Yarn Machines manufacturers in China. These companies consistently demonstrate excellence in technology, product quality, and customer support.

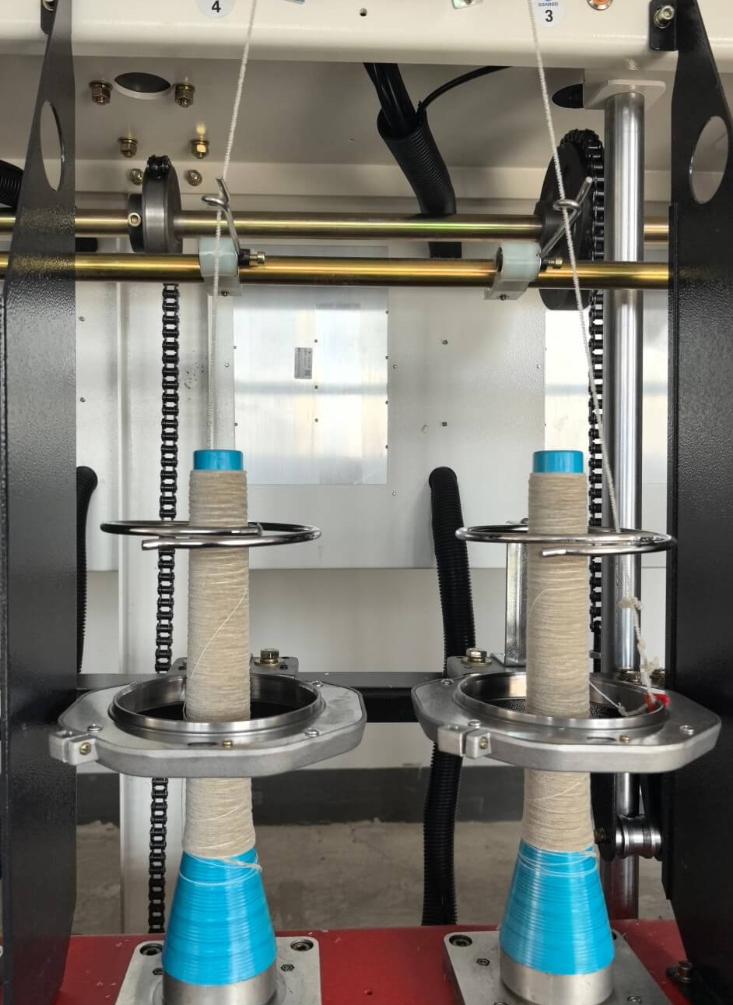

LANXIANG MACHINERY: Leader in High-Performance and Innovation

LANXIANG MACHINERY stands as a leader in high-performance and innovation within the textile machinery sector. The company consistently pushes technological boundaries. Their latest offering, the LX600 high-speed Chenille machine, exemplifies this commitment. They developed this machine with bold innovation, drawing inspiration from imported equipment. The LX600 boasts key features such as high speed, energy saving, and stable equipment. It is specifically designed for the domestic market. Launched in November 2022, it has garnered high customer evaluation. LANXIANG MACHINERY’s focus on advanced engineering ensures their machines deliver superior efficiency and yarn quality.

KINGKANGDA: Renowned for Customization and Cost-Effectiveness

KINGKANGDA distinguishes itself through extensive customization options and cost-effective solutions. They understand diverse production needs. They offer drawing-based customization, allowing clients to provide specific designs. Customers can also opt for sample-based customization, where KINGKANGDA replicates existing samples. Furthermore, they provide full customization services. This includes non-standard design and custom machine development. These services meet unique fancy yarn production requirements. KINGKANGDA also upgrades existing machinery. This improves functionality, automation, and efficiency based on customer needs. Their flexible approach ensures clients receive machines perfectly tailored to their operational demands and budget.

JIANGSU NEW VICTOR INDUSTRIAL CO., LTD.: Excellence in Reliability and Support

JIANGSU NEW VICTOR INDUSTRIAL CO., LTD. earns recognition for its excellence in reliability and support. This company consistently delivers robust machinery. They also provide exceptional after-sales service. Their commitment ensures minimal downtime for clients. They offer prompt technical assistance. This includes an engineer response within 24 hours, as previously noted. This rapid support helps maintain continuous production. JIANGSU NEW VICTOR builds long-term partnerships through its reliable products and dedicated customer care. Their focus on durable equipment and responsive service makes them a trusted choice for many textile producers.

Other Notable Chenille Yarn Machines Manufacturers

Beyond the primary players, several other reputable companies contribute significantly to the market. These Chenille Yarn Machines manufacturers offer diverse solutions for textile production. They maintain high standards for quality and innovation.

- Xinchang Lanxiang Machinery Co., Ltd. This company stands as a reputable Chinese supplier, manufacturer, and factory. They specialize in high-quality Chenille Yarn Machines. Their commitment to robust construction and reliable performance makes them a trusted choice. Xinchang Lanxiang Machinery focuses on delivering durable equipment. This equipment meets the demands of continuous textile operations. They ensure their machines provide consistent yarn quality and efficient production.

- Jingwei Textile Machinery Jingwei Textile Machinery is a leading manufacturer in the textile industry. They offer a broad range of machinery, including advanced Chenille Yarn Machines. Jingwei’s long history in the sector reflects their deep expertise. They consistently integrate modern technology into their products. This ensures their machines deliver high performance and operational efficiency. Their extensive product line supports various production scales and requirements.

- Zhejiang Tongda Textile Machinery Zhejiang Tongda Textile Machinery also holds a strong position as a leading manufacturer. They are known for their innovative approaches to textile machinery. Their Chenille Yarn Machines incorporate advanced features. These features enhance productivity and yarn quality. Zhejiang Tongda focuses on research and development. This allows them to offer cutting-edge solutions to their clients. They provide reliable and technologically advanced machinery for the global market.

These manufacturers collectively strengthen China’s position as a global hub for textile machinery. They offer a wide array of options for businesses seeking efficient and high-quality chenille yarn production. Each company brings unique strengths to the market. This includes specialized designs, robust engineering, and comprehensive support services.

How to Choose the Right Chenille Yarn Machines Manufacturer for Your Needs

Selecting the appropriate manufacturer for chenille yarn machines requires careful consideration. Businesses must align a manufacturer’s capabilities with their specific operational demands. This ensures a successful and efficient production setup.

Assessing Your Production Requirements

Businesses first define their specific production needs. They consider the type of chenille yarn they plan to produce. They also determine the required production volume and their available budget. The desired level of automation in the machinery also plays a crucial role. Understanding these factors helps narrow down potential manufacturers. It ensures the chosen equipment meets all operational specifications.

Importance of Factory Visits and Demonstrations

Visiting a manufacturer’s factory provides invaluable insights. It allows buyers to observe the production environment firsthand. During a factory visit, buyers should:

- Verify Electronic Clearing of Missing Pile: Ensure the manufacturer’s process electronically clears missing pile sections from the chenille yarn. This involves detecting gaps greater than 3 mm and activating a cutter.

- Control Pile Direction: Confirm the manufacturer maintains strict control over pile direction throughout production. All yarn should ship in the same direction to prevent streaks in final fabrics.

- Evaluate Factory Organization: Assess the factory’s layout using the ’5S’ method. Look for efficient material flow, organized items, and minimal employee movement.

- Check Factory Capacity: Observe visual production planning boards. These boards display daily, weekly, or monthly targets and progress. This validates the supplier’s stated capacity.

- Inspect Working Conditions: Note if workers wear protective gear and if workshops are well-ventilated. Look for clear work instructions at each station.

- Examine Production Equipment: Inspect equipment for regular maintenance and good condition. Verify all necessary equipment for your product is on-site.

- Assess Warehouse and Inventory: Review storage conditions for raw materials and finished products. Look for evidence of incoming inspections and proper environmental controls.

Negotiating Terms and Warranty

Negotiating clear terms and understanding warranty provisions protects a buyer’s investment. Manufacturers typically offer varying warranty periods. For example:

| Manufacturer/Platform | Product/Service | Warranty Period |

|---|---|---|

| JIANGSU NEW VICTOR INDUSTRIAL CO., LTD. (via Made-in-China.com) | Chenille Yarn Machine | 1 year (with life-long technical support) |

| Jiangsu New Victor Industrial Co., Ltd. | Chenille Yarn Spinning Making Machine | 3 years |

| Alibaba.com | Products purchased on platform | 1 year (includes free parts replacement and repair) |

| TOPT-TEXTILEPART.com | Spare parts | Generally 3 months; some parts ‘Unavailable’ |

Buyers should also clarify payment terms.

Installments shall be accepted by Buyer and paid for at contract prices and terms. All samples furnished shall be paid for by Buyer at contract price. Delay in delivering samples or other sample requirements shall not constitute a breach of this contract. Any defect in quality or delay in performance by Seller shall not affect the balance of this contract. Any installment of yarn not in dispute shall be paid for on the due date, as provided in this contract, without offset, defense or counterclaim and regardless of controversies relating to other yarn. Where Buyer has declared or manifested an intention that it will not accept yarn in accordance with the provisions of this contract no tender shall be necessary but Seller may, at its option, give notice in writing to Buyer that Seller is ready and willing to perform in accordance with this contract and such notice shall constitute valid tender of delivery and performance by Seller. This excerpt highlights the importance of understanding payment schedules, sample costs, and how disputes or delays affect the contract. Buyers ensure all terms are favorable and clearly documented before finalizing a purchase.

The Role of Automation in Modern Chenille Yarn Machines

Modern textile manufacturing increasingly relies on automation. Chenille yarn machines benefit significantly from these technological advancements. Automation enhances efficiency, quality, and overall operational control.

Benefits of Automated Systems

Automated systems bring numerous advantages to chenille yarn production. They significantly increase production efficiency and output volume. Manufacturers observe a notable reduction in labor costs as machines perform tasks previously requiring manual intervention. Automation also ensures consistent yarn quality, minimizing variations that human error might introduce. This leads to a more uniform and higher-grade product. Furthermore, automated machines often operate with greater precision, reducing material waste. They also enhance workplace safety by handling repetitive or hazardous tasks.

Integration with Production Lines

Modern automated chenille yarn machines seamlessly integrate into larger textile production lines. This integration allows for a continuous and synchronized manufacturing process. Centralized control systems manage the flow of materials from fiber preparation to final yarn winding. This connectivity reduces bottlenecks and optimizes the entire production chain. For example, machines can automatically adjust speeds or tension based on real-time feedback from upstream or downstream processes. This creates a highly efficient and responsive manufacturing environment.

Data Analytics and Predictive Maintenance

Data analytics plays a crucial role in optimizing automated chenille yarn machines. These machines collect vast amounts of operational data, including speed, temperature, tension, and energy consumption. Analyzing this data provides valuable insights into machine performance and potential issues. Predictive maintenance utilizes these insights to anticipate equipment failures before they occur. This allows manufacturers to schedule maintenance proactively, minimizing unplanned downtime. It also optimizes spare parts inventory and extends the lifespan of machinery. Ultimately, data analytics and predictive maintenance enhance overall equipment effectiveness (OEE) and reduce operational costs.

Selecting the best Chenille Yarn Machines manufacturers in China involves a thorough evaluation. Businesses must assess their technological capabilities, product quality, and support services. By focusing on reputable companies like LANXIANG MACHINERY, KINGKANGDA, and JIANGSU NEW VICTOR INDUSTRIAL CO., LTD., buyers can make informed decisions. Aligning their offerings with specific operational needs ensures a confident investment. This approach guarantees machinery that delivers efficient and high-quality chenille yarn production.

FAQ

What is chenille yarn?

Chenille yarn features a soft, fuzzy texture. Manufacturers create it by placing short lengths of yarn, called “pile,” between two core yarns. They then twist these core yarns together. This process traps the pile, making it stand out at right angles. The result is a soft, caterpillar-like appearance.

Why should businesses choose Chinese manufacturers for chenille yarn machines?

Chinese manufacturers offer advanced technology, high product quality, and competitive pricing. Companies like LANXIANG MACHINERY and KINGKANGDA provide innovative solutions and reliable machinery. They also offer strong after-sales support. This combination makes them a cost-effective and efficient choice for global buyers.

What key features should buyers look for in a modern chenille yarn machine?

Buyers should prioritize machines with high-speed capabilities, energy-saving features, and advanced automation. Look for independent servo motor drives, precise winding mechanisms, and user-friendly touchscreen interfaces. These features enhance efficiency, yarn quality, and ease of operation.

Post time: Nov-01-2025

Phone: +8613567545633

Phone: +8613567545633 E-mail: lanxiangmachine@foxmail.com

E-mail: lanxiangmachine@foxmail.com