The one-step false twister produced by our Xinchang Lanxiang Machinery Co., Ltd. has been recognized by the market, with a market share of more than 90%. This equipment is applicable to the one-step processing of double twist, setting (pre-shrinking) false twist of polyester filament FDY, and the crepe produced is used as the weft of polyester imitation silk fabric.

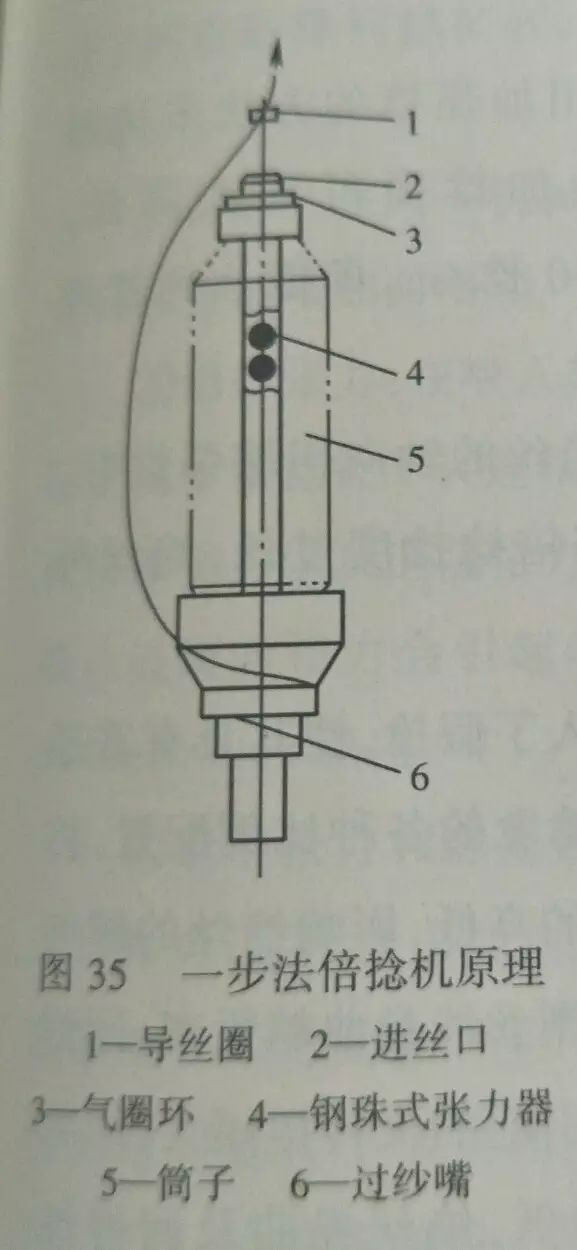

The false twisting principle of one-step false twisting machine is realized by using false twisting device. After double twisting, the filament enters the magnetic rotor type false twister. The false twister is equipped with a horizontal pin made of ruby-grade high wear-resistant material. The filament is wound around the horizontal pin for one or two turns and then comes out of the false twister, which is then led out by the roller and is wound into shape (Fig.).

As the wire rod is wound on the horizontal pin, when the rotor rotates, it drives the wire rod to rotate together, so that the wire rod can be twisted back. With the grip point (the horizontal pin of the rotor) as the boundary, the upper and lower segments of the wire can obtain positive and negative twist in different directions respectively. At the same time, the wire rod moves at a constant speed, so that the twist value of the area behind the grip point is zero. Therefore, for the whole filament, the final twist imposed on the filament due to the rotation of the false twister is zero, so it is called false twist.

The function of the false twister is to add false twist to the yarn segment before the horizontal pin, and heat it in the hot box to deform it. After cooling, it can untwist it through the horizontal pin, giving the filament a certain degree of bulkiness, elasticity and scalability.

The false-twisted filament shall undergo heat treatment. Filament entering the heating area has both double twist and false twist. The function of the heater is to set the filament for double twist, and to denature the filament for false twist. After untwisting, the filament will have crimp effect. At the same time, the filament is heated under low tension and thermally denatured to pre-shrink the filament and reduce the heat shrinkage, which is conducive to the appearance of crepe effect. The common temperature of the heater is 180~220 ℃. It can be set according to process requirements. The constant temperature state of the heater shall ensure uniform heat treatment of the wire. The twister spindle and false twister both rotate at extremely high speed, and the balloon tension is large and there is a certain tension fluctuation.

The double twister spindle and the false twister on the one-step double twister are equipped with independent toothed overfeeding rollers. One of the biggest characteristics of the overfeed roller is that its grip on the silk thread is negative, which changes with the surrounding angle of the silk thread on the surface of the roller, the tension at both ends of the silk thread, and the friction coefficient between the silk thread and the overfeed roller material.

Post time: Feb-04-2023