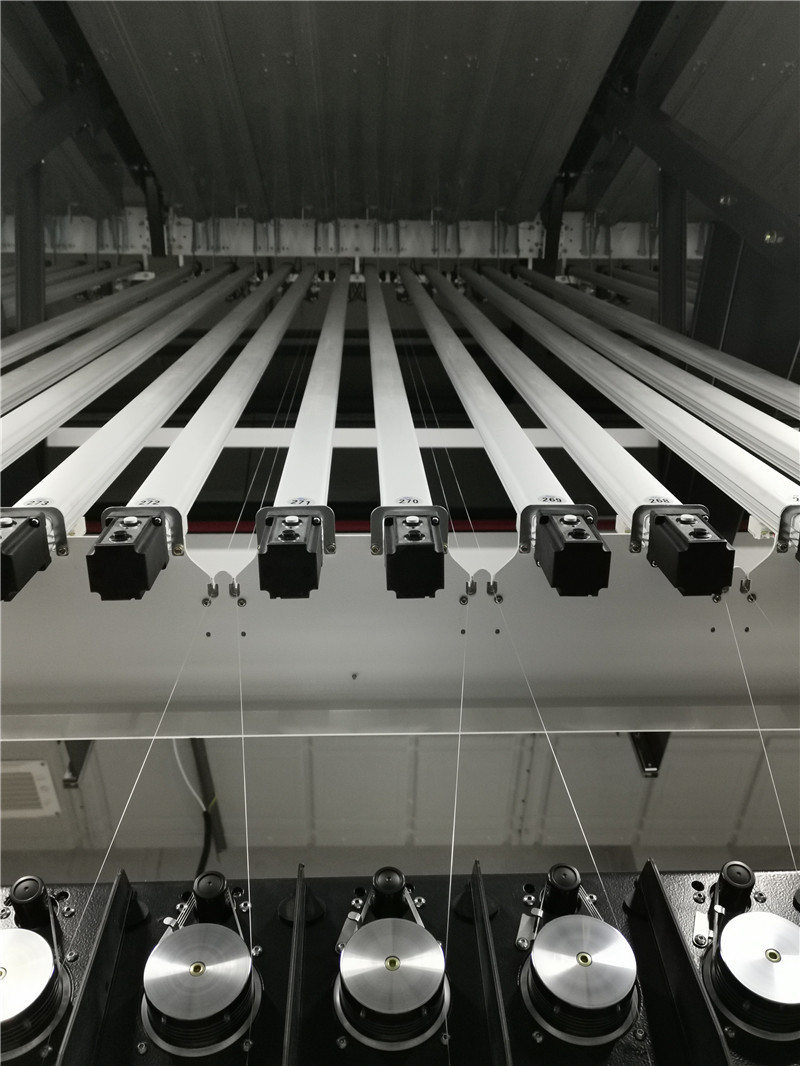

LX1000 High-speed Draw Texturing and Air Covering All-in-one Machine

1.Three rollers named machine D1,D2,D2.2,all adopt the godet mechanism. The godet is controlled by the micro-motors. It control the fiber will and ensure the stretching.

2.The machine’s two sides (A-B) running relatively independent, both adopt energy-saving motor instead of belt,the process parameters can be set separately. Two sides could process different productions.

3.The specially energy-saving nozzle can save air and power.

4.Two-step D2 roller structure improve the node uniformity and fastness of the nylon spandex.

5.The special fiber structure is adopted to improve the efficiency of fiber processing.

6.The adjustable spandex universal support is adopted to ensure the spandex feeding well during high speed running.

7.Electric structure ensures convenient and quick threading.(Optional)

8.Machine’s deformation heater adopts biphenyl air heating.The temperature precision is exact to ±1 ℃ assure every spindle’s temperature to be same.This is beneficial for dying.

9.Excellent machine structure reliable drive system and low noise. It is easy for process adjustment, and maintained by single spindle to improve productivity.

| Type | V type |

| Spindle Number | 288spindles ,24 spindles/section X 12 =288 spindles |

| Spindle Gauge | 110mm |

| False Twisting Type | stacked disc friction false twister |

| Length of Heater | 2000mm |

| Heater Temperature Range | 160℃-250℃ |

| Method of Heating | biphenyl air heating |

| Maximum Speed | 1000m/min |

| Process speed | 800m/min~900m/min |

| Take-up Package | Φ250xΦ250 |

| Winding Type | groove drum type friction winding , packaged with double tapers bobbin |

| Spinning Range | spandex 15D~70D; chinlon 20D~200D |

| Installed power | 163.84KW |

| Effective power | 80KW~85KW |

| Machine Size | 18730mmx7620mmx5630mm |

Phone: +8613567545633

Phone: +8613567545633 E-mail: lanxiangmachine@foxmail.com

E-mail: lanxiangmachine@foxmail.com